INDUSTRIAL & COMMERCIAL APPLICATIONS

Made in Brass, Aluminium, Stainless Steel and uPVC.

Fluids handled:

Control rings are made in Nitrile Rubber, EPDM and Viton as required to handle:

- service water hot & cold; sea water; petroleum products and other chemicals.

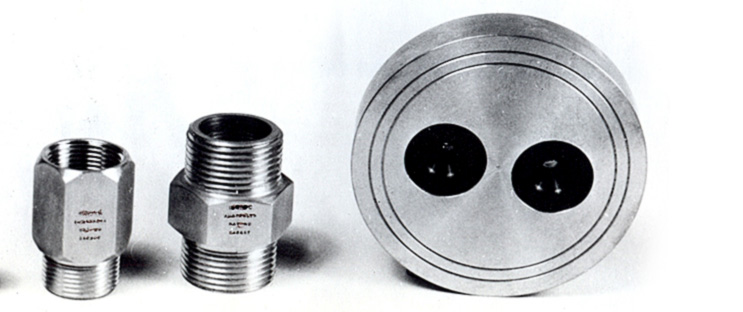

Screwed Types:

In sizes from ¼” BSP up to 2” BSP with threads as required:

F/F; F/M; M/F and M/M. The first is the inlet end.

Used where the pipe is screwed and can be screwed directly onto an item of equipment.

The range of flows is from 0.4 LPM up to 200 LPM.

TopHat Types:

Made for fitting into copper tube where there is a compression joint.

These FLVs have a shoulder the size of the outside of the tube so that they cannot slip into the tube.

Made for 15mm, 22mm and 28mm copper tube.

Insert Types:

Custom made to fit into customers equipment.

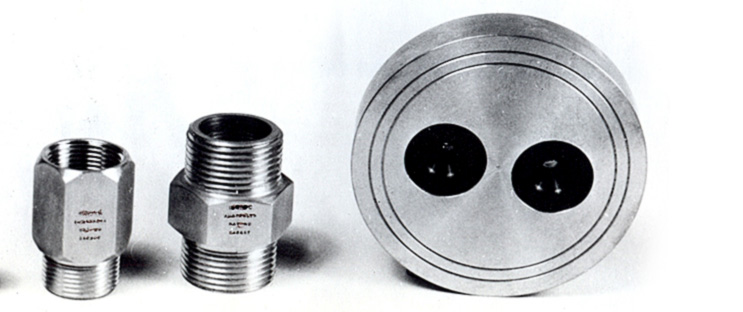

Wafer Types

Designed to fit between pipe flanges with an inset ‘O’ Ring seal each side;

Sizes from 1 ½” up to 10” nominal bore pipe.

Wafer FLVs can have up to 40 individual flow rings

giving a maximum of 4,560 LPM in the 10” Wafer.

Wafers are normally made to fit inside the bolt circle but can be full faced.

Typical uses:

Controlling flow in critical industrial processes

- Desalination, UV purification etc

- Protecting equipment against damage from excess flow

- Balancing distribution in complex pipe distribution systems

- Fire deluge systems

- Farm, agricultural and sports area irrigation

- Service water distribution in high or large buildings

- Blending liquids in correct proportions

- Drinking fountains

- Combination Boilers

- Engine cooling

The full range of flow rings and their potential applications

By selecting rings of different flows together in a wafer type, the customer may get exactly the flow desired. See further information on Flow Rings by clicking here